COMPONENTS

ROCKFIN

We are constantly developing the portfolio of our own products that we use in the auxiliary systems of turbine sets. These include liquid tanks, liquid and gas filters, liquid and gas separators, flow control valves and solutions that reduce noise and vibration. The development work was carried out with the support of EU funds under the Smart Growth Operational Program 2014-2020.

OUR PRODUCTS

Water Coalescing System efficiently, cheaply and energy-efficiently removes water from lubricating oils, fuels and other media. Application finds use in many sectors of industry such as: energy in auxiliary units of turbosets, oil&gas sector, paper factories and others where there is a risk of water entering into working fluid. Coalescing systems provide easy and cost-effective maintenance to keep water levels at low level to protect lubricating systems from harmful effect of water content during regular operation.

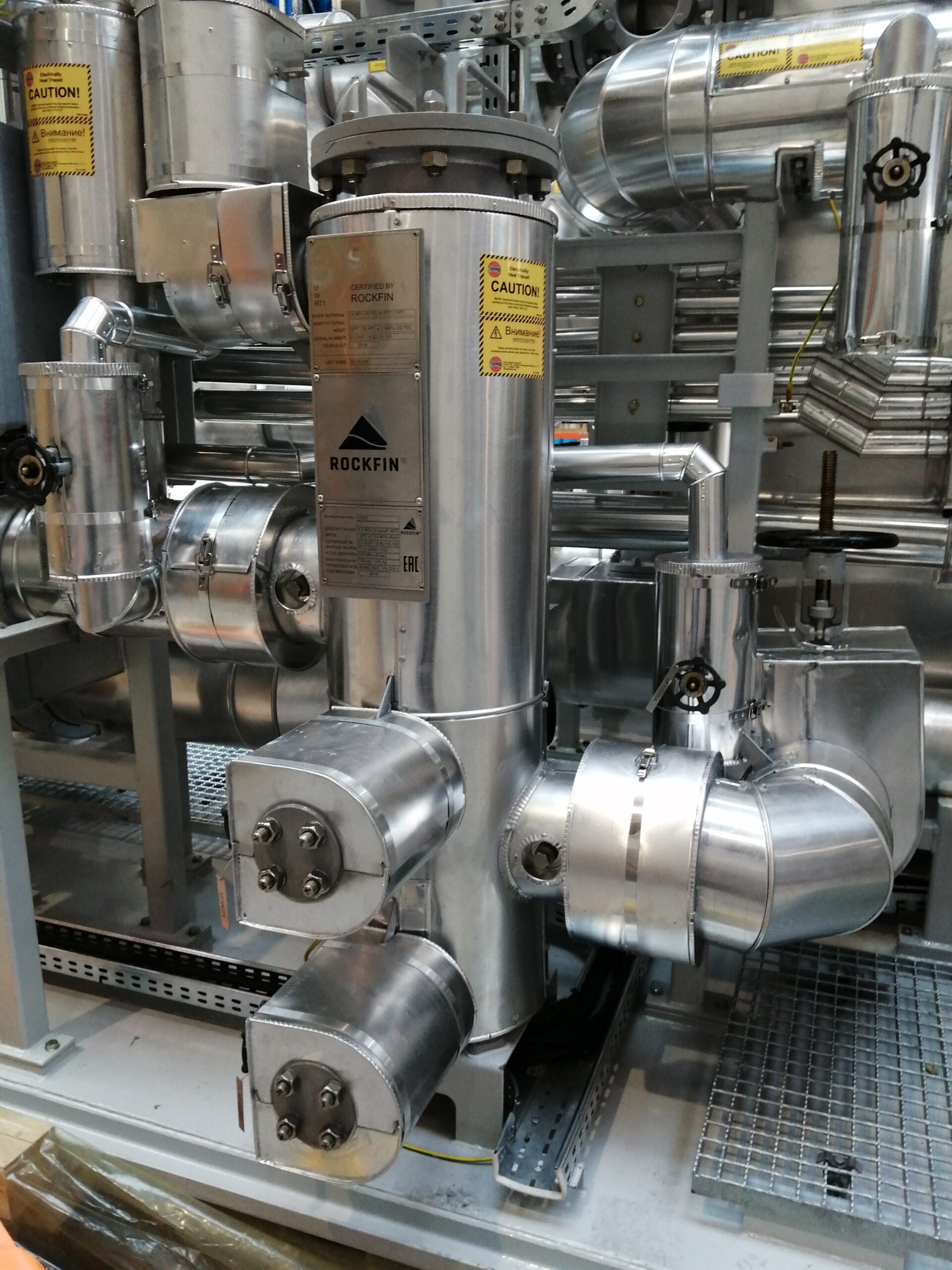

Rockfin's many years of engineering experience ensures a high standard of workmanship in our Oil Mist Separators. Our company offers standardized designs to customers and can accommodate the installation of OMS in required locations. Application finds use mostly in sectors of industry such as: energy sector in auxiliary units of turbosets and in lubrication units of rotary machines in oil&gas sector.

Thanks to many years of experience of Rockfin in the field of engineering, RFSI cartridge filters guarantee a high standard of performance in accordance with international standards and generate low pressure losses in installation. Gas basket strainer are used either as the first coarse filtration, suction filters or the „last chance” filters. They can be successfully used in both the energy sector as a part of turboset auxiliafry units, oil&gas sector, petrochemical and other sectors.

Flow control valves (changeover), equipped with safe and reliable changeover mechanism, are used in all systems when continuous operation is required while redundant line is at maintenance process, like is required e.g. in auxiliary systems of turbosets or lubrication systems or rotating equipment in oil&gas sector. This solution is able to adapt to various of applications, such as duplex filters, duplex heat exchangers – since spacing between valves can be easily adapted. Changeover Valves provide easy and cost -effective maintenance to keep system online all the time.

We have many years of experience in manufacturing of atmospheric tanks and pressure vessels. We make atmospheric tanks as welded-bent structures with at least 10% less weight at the same volumes compared to typical fully welded tanks. The tanks have appropriately shaped internal elements that ensure efficient circulation of the working liquid, guaranteeing degassing of the liquid with reduced retention time, which is particularly important in the auxiliary systems of turbine sets and other rotating machines. Pressure vessels are designed according to the EN 13445 standard and the PED 2014/68/EU pressure directive or the ASME BPVC Sec standard. VIII Div. 1. All tanks are made of carbon or stainless steel, with a width or diameter of up to 3 meters, a length of up to 12 meters and a weight of up to 30 tons.

Trusted by Industries